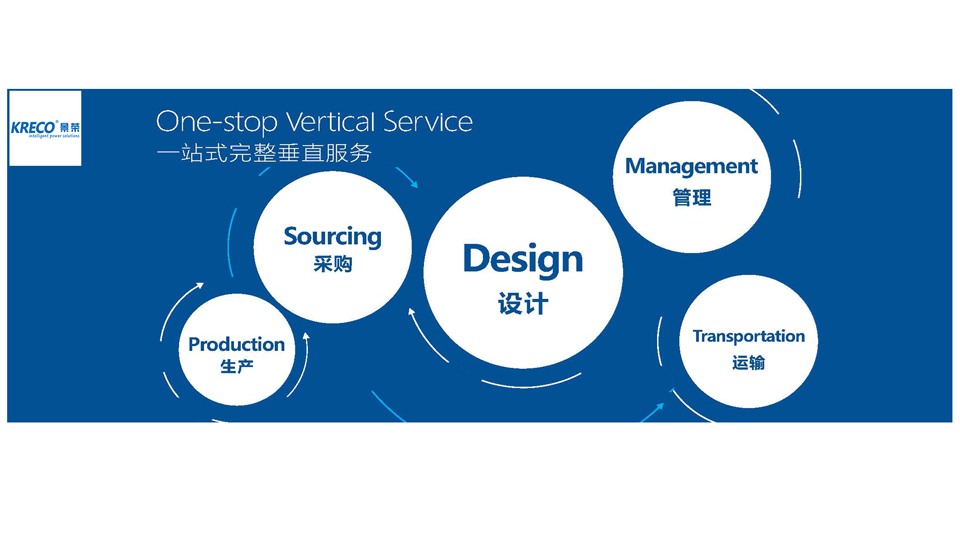

Switch power adapter, also have the charger; Is an external power supply conversion device, can often from the alternating current into direct current, at the same time can change voltage. Switch power adapter is in everybody's life. Because everyone needs to use the electronic accessories, such as mobile phone/tablet charger, or home broadband cats, the router will need to use switch power adapter. Switch power adapter production process: from development to production formally, in two stages.

A, the development process:

First of all, according to using need, carries on the design, determine the good after. Open the mould, the production casing.

Secondly, according to the performance requirements, electronic engineers to develop electronic circuit part, choose the right solution, design of electronic schematic diagram, and draw the circuit board (PCB) drawings, making PCB samples to PCB manufacturer.

Then, electronic engineer handmade samples, the samples and then to the performance test, assembly test, aging test and other tests.

Then, after the sample test ok. Development of PCB production mold. For small batch trial-produce. Will test in the production process has some problems. Then make a corresponding adjustment.

Finally, the circuit board (PCB), PCB and if there is a change, need to open mold. Production specifications, work instructions, inspection instructions and other relevant files.

A, the development process:

First of all, according to using need, carries on the design, determine the good after. Open the mould, the production casing.

Secondly, according to the performance requirements, electronic engineers to develop electronic circuit part, choose the right solution, design of electronic schematic diagram, and draw the circuit board (PCB) drawings, making PCB samples to PCB manufacturer.

Then, electronic engineer handmade samples, the samples and then to the performance test, assembly test, aging test and other tests.

Then, after the sample test ok. Development of PCB production mold. For small batch trial-produce. Will test in the production process has some problems. Then make a corresponding adjustment.

Finally, the circuit board (PCB), PCB and if there is a change, need to open mold. Production specifications, work instructions, inspection instructions and other relevant files.

A. welding line: the DC line, the welding on the bare plate. Under the AC line welded to the shell shell on the metal parts.

B. make gum: easy to fall off during the transit, broke the plastic components. Line through a transformer, filter, AC and DC line of solder joints, etc.

C. packing: switch power adapter shell together.

D.Q C test 2: through the computer integrated test instrument, test whether the output performance. If not in the past, to a mechanic repaired at the scene. Again the test until pass the test.

E. repair: repair test without using switch power adapter.

F. a screw: the shell is fixed. Some shell is the use of ultrasound. On the i.Q test 3 C is behind;

H. aging test: the dozen good screw products, transferred to aging workshop, aging test. Aging test after a certain period of time. Then transfer back to full inspection of the QC test the final assembly drawing.

I.Q test 3 C: finally a full inspection, the product after aging test, to carry on the full inspection, if not through, back to e. repair. Test by following a process.

J. ultrasonic: shell if it is the use of screws, do not need to this procedure.

K. appearance QC: here need to pick out the appearance has a problem. Replace the shell.

L. stick nameplate: visual inspection after ok. The products labeled accordingly.

M. packaging: through layer upon layer after inspection. The packaging of finished products.

5, sampling observation of quality: the finished production of finished products, in accordance with the relevant national quality inspection standard for checking. Sampling includes functionality, appearance, etc. After checking by quality department, before leaving the factory.

声明: Disclaimer: This article comes from individual, KRECO has the right of final interpretation.

.jpg)